Introduction

Technological innovation plays a key role in enhancing efficiency and sustainability in manufacturing companies. Mative, a leader in providing advanced technological solutions, offers Internet of Things (IoT) and Machine Learning (ML) services that can revolutionize operations in the window, door, and frame manufacturing sector. This report explores the energy and economic benefits derived from adopting these technologies in a manufacturing company.

Internet of Things (IoT) in Manufacturing

Definition and Operation

IoT involves the interconnection of smart devices via the internet, capable of collecting, exchanging, and analyzing data in real-time. In manufacturing, IoT sensors can monitor various parameters such as machinery performance, energy consumption, production quality, and supply chain conditions.

Energy Benefits

- Optimization of Machinery Energy Use: IoT sensors can monitor the energy consumption of machinery and equipment, identifying inefficiencies and suggesting improvements to reduce energy use.

- Efficient Facility Management: Sensors can control heating, ventilation, and air conditioning (HVAC) systems based on real-time data, reducing unnecessary energy consumption.

- Improved Production Processes: Monitoring equipment conditions in real-time helps optimize production processes, reducing energy waste associated with machinery downtime or suboptimal performance.

Economic Benefits

- Reduction of Operating Costs: Efficient management of energy consumption and machinery performance leads to significant reductions in operating costs.

- Enhanced Production Efficiency: Real-time monitoring and optimization improve production efficiency, leading to higher output and reduced waste.

- Predictive Maintenance: Data from IoT sensors enable predictive maintenance, reducing downtime and extending the lifespan of machinery, thereby saving on repair and replacement costs.

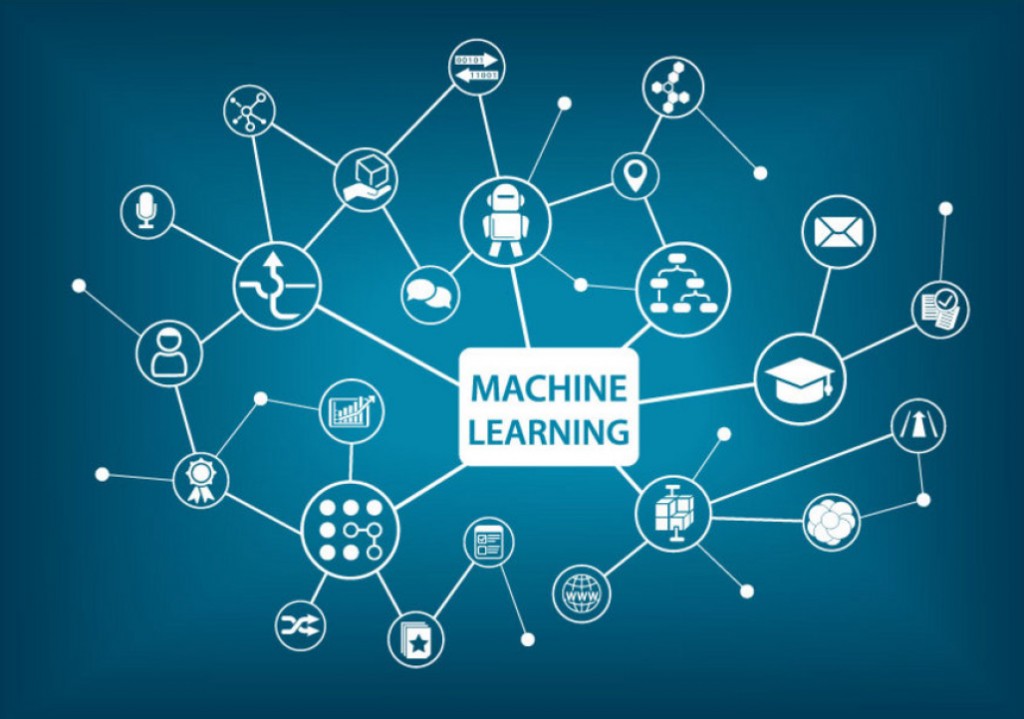

Machine Learning (ML) in Manufacturing

Definition and Operation

Machine Learning is a branch of artificial intelligence that uses algorithms to analyze large amounts of data and make intelligent predictions or decisions. In manufacturing, ML can analyze data from IoT devices to identify patterns, forecast trends, and optimize processes.

Energy Benefits

- Predictive Energy Management: ML algorithms can analyze historical and real-time data to forecast future energy needs, allowing for more precise energy management and reducing overall consumption.

- Optimization of Production Schedules: ML can optimize production schedules based on data analysis, leading to better energy utilization and reduced peak demand.

Economic Benefits

- Process Optimization: ML helps in identifying the most efficient production processes, leading to cost savings and increased productivity.

- Demand Forecasting: ML algorithms can predict market demand more accurately, allowing for better inventory and production planning, reducing excess inventory and associated costs.

- Quality Improvement: ML can analyze data to identify quality issues early in the production process, reducing defects and waste, and improving overall product quality.

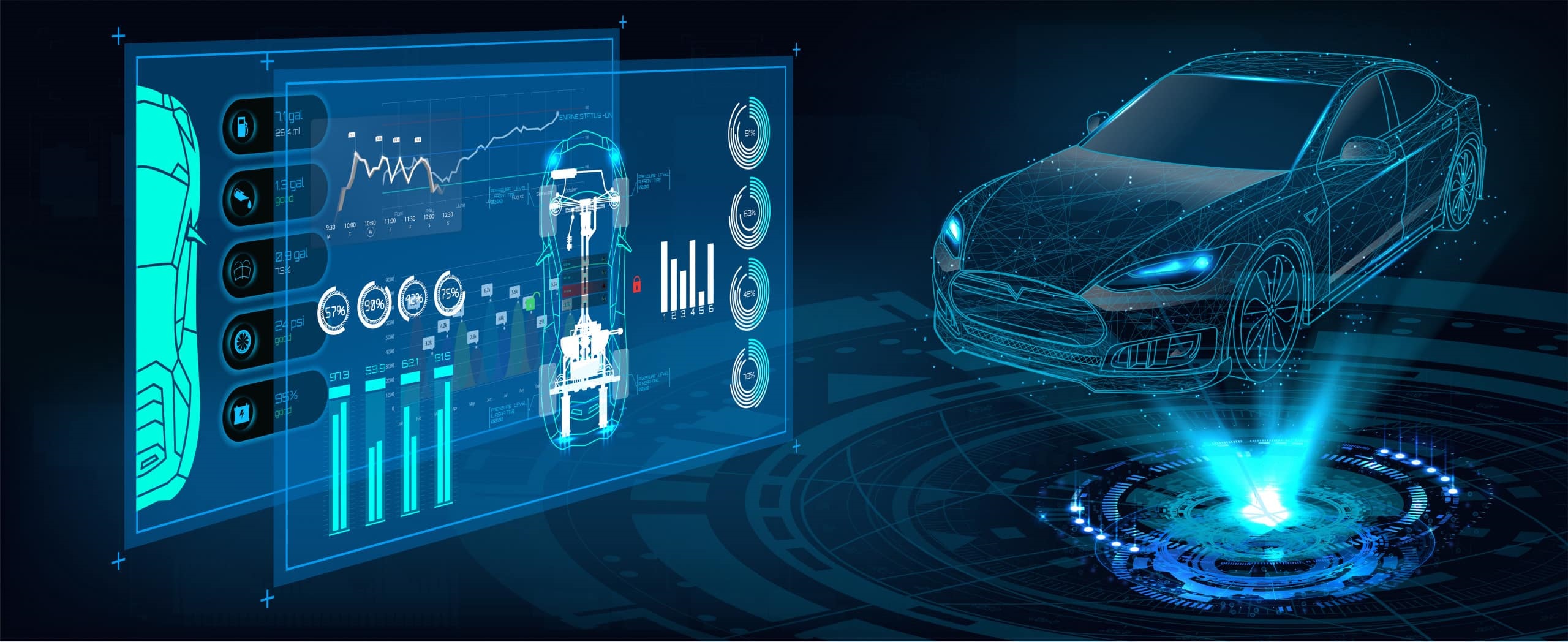

IoT & ML: Implementation in a Window, Door, and Frame Manufacturing Company

Consider a manufacturing company specializing in windows, doors, and frames that decides to adopt Mative Srl's IoT and ML solutions. Our forecast analysis after one year of implementation and adoption of our technologies, shows the following benefits:

- 20% Reduction in Energy Consumption: Through optimized machinery use and efficient facility management based on real-time data.

- 15% Decrease in Operating Costs: Due to enhanced production efficiency and reduced waste.

- 25% Improvement in Production Efficiency: Resulting from optimized production processes and better use of resources.

- 10% Savings in Maintenance Costs: Thanks to predictive maintenance and extended machinery lifespan.

Conclusion

The adoption of IoT and ML technologies proposed by Mative Srl represents a significant advancement for manufacturing companies specializing in windows, doors, and frames. The benefits from implementing these technologies not only contribute to energy and economic efficiency but also enhance competitiveness and profitability, positioning the company to effectively meet future industry challenges.